Why Industrial Scales Are Essential for Compliant and Safe Manufacturing

Why Industrial Scales Are Essential for Compliant and Safe Manufacturing

Blog Article

Why to Select Industrial Scales for Accurate Weight Measurement in Numerous Industries

In a period where precision is critical, the choice of commercial ranges for precise weight dimension plays a crucial duty across diverse fields. These ranges not just enhance operational performance but likewise guarantee conformity with governing criteria, influencing everything from manufacturing to shipping. Their robust design and progressed modern technology cater to various applications, reinforcing the demand for careful weight management. Understanding the subtleties of these ranges is necessary for any type of organization aiming to optimize procedures and alleviate expensive errors. The concern continues to be: what specific elements should one think about when picking the right range for their distinct operational requirements?

Value of Accurate Weight Measurement

In the world of industrial procedures, the significance of exact weight measurement can not be overstated. Precise weight dimension is fundamental throughout various fields, affecting both operational effectiveness and item high quality - Industrial Scales. It offers as an essential consider inventory administration, ensuring that materials are properly made up, thereby minimizing waste and lowering costs

In production, exact weight dimension straight affects production processes. Anomalies in weight can cause ineffective products or too much resource allotment, impacting total productivity. Additionally, in markets such as pharmaceuticals and food manufacturing, adherence to rigorous weight requirements is essential for governing compliance and customer safety.

Moreover, accurate weight measurements assist in reliable logistics and supply chain administration. Correctly considered shipments make sure that transport costs are maximized and that inventory levels are maintained accurately, consequently preventing stock lacks or overstock situations.

Types of Industrial Scales

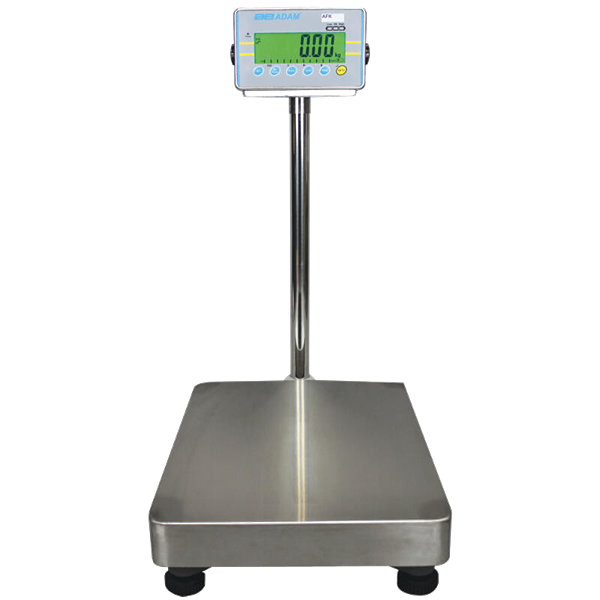

A wide range of commercial ranges are offered, each developed to satisfy details dimension requires across varied industries. Usual kinds include flooring scales, which are robust and suitable for weighing large items or pallets in stockrooms and warehouse. Bench ranges are smaller sized and perfect for lighter products, often made use of in retail setups or producing for accurate section control.

An additional group is portable scales, which provide the adaptability to be moved easily around work websites, making them perfect for field operations or temporary configurations. Precision scales, on the other hand, are developed for high precision and are frequently made use of in laboratories and top quality control atmospheres.

Load cells are essential components in numerous industrial ranges, transforming push into an electric signal for accurate analyses. Furthermore, truck scales give the means to weigh heavy vehicles and their loads, making sure conformity with policies and enhancing logistics.

Finally, checkweighers instantly compare the weight of products versus preset limits, enhancing quality control in assembly line (Industrial Scales). Each type of commercial scale offers an unique feature, providing to the particular needs of sectors such as manufacturing, logistics, food processing, and pharmaceuticals

Advantages of Making Use Of Industrial Scales

Regularly utilizing commercial scales offers considerable advantages throughout various sectors. Among the primary benefits is enhanced accuracy in weight measurement, which is important for keeping top quality standards and regulative conformity. Exact measurements avoid expensive errors in manufacturing, delivery, and supply monitoring, inevitably bring about raised operational efficiency.

Furthermore, commercial ranges are developed for longevity and toughness, enabling them to endure severe atmospheres usually discovered in production and warehousing. This strength guarantees a long life expectancy, decreasing the requirement for constant substitutes and upkeep prices.

Additionally, utilizing commercial scales enhances safety and security and reduces waste. By ensuring that products are considered properly, business can prevent straining lorries, which can lead to penalties and crashes.

Applications Throughout Numerous Industries

Industrial scales play a crucial function in countless fields, including production, logistics, food processing, and pharmaceuticals. In manufacturing, these scales are necessary for ensuring that basic materials are measured accurately, therefore keeping item quality and uniformity (Industrial Scales). Accuracy in weight dimension directly affects production efficiency and price administration

In logistics, industrial ranges help with the accurate evaluating of shipments, which is vital for adhering to optimizing and delivering laws products prices. Exact weight information aids simplify operations and enhances supply chain administration.

The food handling industry counts heavily on commercial scales for conformity with wellness and safety and security laws. They are made use of to consider active ingredients exactly, making sure that formulations fulfill both high quality criteria and lawful needs. This is vital not just for customer security yet likewise for keeping brand name stability.

Pharmaceutical companies utilize industrial ranges to ensure precise does in medicine production, where also the tiniest inconsistency can have significant effects. Compliance with rigid regulatory criteria makes accurate weight measurement important in this sector.

## Variables to Think About When Selecting Scales

Selecting the right range for particular applications needs this post careful consideration of several aspects. First and leading, the capacity of the scale is critical; it should suit the maximum weight of the things being determined without surpassing its restrictions. Furthermore, the readability, or smallest increment the range can precisely display, is essential for accuracy, particularly in industries where weight discrepancies can result in substantial monetary losses or safety worries.

Environmental problems additionally play a substantial role in range selection. Ranges made use of in corrosive or humid settings may call for customized products to guarantee toughness. Similarly, transportability may be necessary in certain applications, necessitating light-weight and battery-operated designs.

Conclusion

To conclude, the selection of industrial ranges is pivotal for guaranteeing accurate weight measurement throughout varied industries. Their ability to offer precise analyses not just boosts functional performance but likewise sustains governing conformity and supply monitoring. The flexibility and toughness of these ranges promote their application in different markets, inevitably adding to cost reduction and improved product quality. Thus, buying high-grade commercial scales is essential for companies aiming to preserve high criteria and make the most of success.

Report this page